Harmonious Zenith Dentistry

Digital Dental Tools & Technology we use

CAD/CAM Software for Precision Dental Design

Our team relies on industry-leading CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) software to create dental restorations that meet the exact specifications of each case. These tools are the backbone of our design process, allowing us to visualize, plan, and produce restorations with unparalleled precision.

3Shape: We utilize 3Shape software, including 3Shape Implant Studio, for detailed and patient-specific implant planning and design. This tool allows us to visualize and plan implant placements with accuracy, ensuring optimal fit and function.

Blender for Dental: We use Blender for Dental for complex and highly customized dental designs. Blender for Dental offers flexibility and detail control, allowing us to create fully custom prosthetics that meet the highest standards.

ExoCAD & ExoPlan: ExoCAD is another integral software in our workflow, providing flexibility and precision in designing crowns, bridges, and partials. ExoCAD’s Partial CAD and ExoPlan modules streamline the design process, helping us tailor each prosthetic to meet specific patient needs.

Zirkonzahn: Known for its compatibility with high-quality zirconia and other materials, Zirkonzahn software is specialized for durable, natural-looking restorations. It enhances the aesthetic appeal of our products and helps ensure long-lasting solutions.

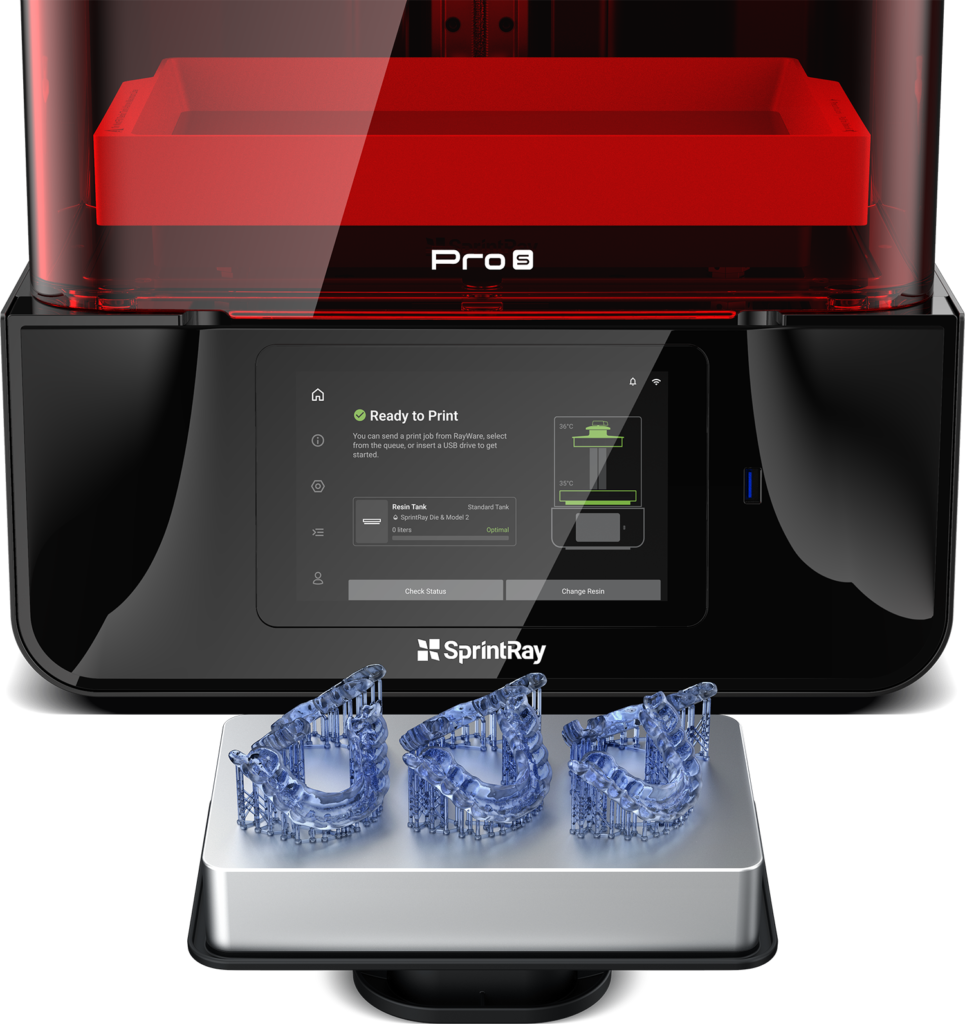

3D Printing & Advanced Manufacturing with SprintRay Printers

3D printing has revolutionized the dental industry by allowing for rapid and precise production of dental models, crowns, bridges, and other prosthetics. In our lab, SprintRay Printers are a cornerstone of this capability.

Biocompatible Materials for Safe and Natural-Looking Results

The materials we use in our manufacturing process are carefully selected for durability, aesthetics, and safety. Using biocompatible materials ensures that our restorations not only look natural but also meet the highest standards for patient safety and comfort.

Materials Used: We work with high-quality materials like zirconia, resin, and biocompatible metals. These materials are known for their strength, longevity, and natural appearance, making them ideal for a wide range of dental restorations.

Benefits: Biocompatible materials reduce the risk of allergic reactions and other complications, ensuring that each restoration is safe, durable, and visually pleasing.

Digital Scanning for Accurate Impressions

Digital scanning is an essential part of our design process, enabling us to capture precise images of a patient’s oral anatomy without traditional molds. Our intraoral scanners collect highly accurate data that integrates seamlessly with our CAD software, ensuring every design is rooted in precise patient data.

Overview: Digital scanning is a non-invasive, efficient, and accurate method for capturing dental impressions. It improves patient comfort and enhances the quality of the final restorations.

Benefits: With digital impressions, we eliminate the discomfort and potential inaccuracies of traditional molding, allowing for faster and more accurate data capture.

Devices Used: Our scanning systems integrate seamlessly with 3Shape, ExoCAD, and Blender software. This compatibility ensures that we can utilize the data effectively across our digital workflow, enhancing precision at every stage.

Clear Aligners & Advanced Orthodontic Solutions with Invisalign

For patients requiring orthodontic treatment, we offer Invisalign clear aligners as an effective, discreet solution. Invisalign’s aligners provide patients with a comfortable, nearly invisible method to achieve their desired results.

High-Precision Milling Machines: Yenadent D15, Sirona CEREC, and Cortec

Milling machines are an essential part of our lab, allowing us to shape and finish custom dental restorations with extreme precision. Our lab features Yenadent D15, Sirona CEREC, and Cortec milling machines, each chosen for its unique advantages and high-quality output.